In choosing pipe consider these:

1. In larger sizes ( > 6" ) steel / iron pipe is cheaper for the same pressure rating. And used ( gas line) steel pipe is even more cost effective.

2. I'm a pretty good welder, but even hiring a welder to do the job costs as much as hiring an HDPE fusing machine and operator.

3. HDPE needs more supports to keep the pipe from sagging under the weight of the water where it is up in the air.

4. For gentle bends (< 45°) steel pipe ends can be cut at a slight angle and welded together avoiding the use of expensive fittings.

5. If there is ever a forrest fire plastic pipe on top of the ground may well burn up.

6. In cold temperatures a tree falling on exposed HDPE will crack it.

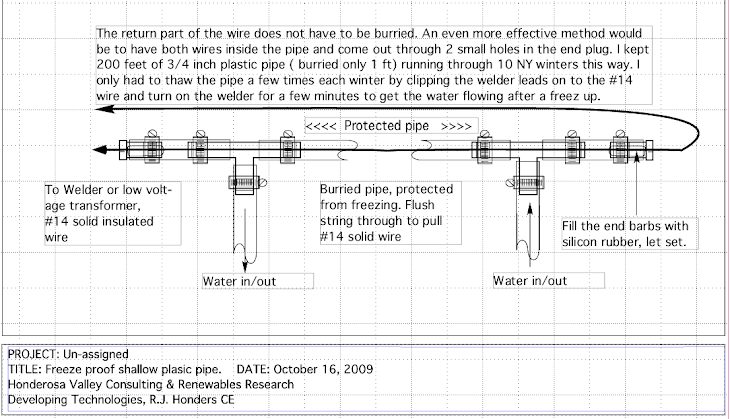

Of course the best way to protect any pipe is to burry it and that would make plastic more attractive as it also limits thermal expansion and contraction which can be a problem with HDPE on the surface. (I have seen exposed plastic pipe pull apart at joints when the temperature dropped at night. The 8" PVC pipe was glued up on a hot day, empty, when the overnight temperatures dropped it pulled two of 12 joints apart.)

All things considered, if you have more than 100' of head and need > 8" diameter pipe you are a good candidate to use steel pipe especially if you can weld it yourself reasonably well. If you have to come down rocky cliffs, like I did, then that would favor steel pipe also.

For lower heads and / or smaller diameters HDPE or even PVC would be easier to handle and more durable when buried. If plastic pipe is not buried it will need to be protected from UV exposure.

Marking & cutting 8" 0.25" wall steel pipe.

Make the cut with an angle grinder and thin cutoff blade.

Welding pipe on pipe dolly

Using homemade alignment clamp.

Welding pipe on the ground

Below, the blown out schedule 40 T

static pressure 94 PSI, must have surged.

The fiberglass reinforced schedule 40 elbow.

5 comments:

Excellent post. Becoming a brand-new blogger I'm understanding a lot as a result of these sorts of blogposts carry on the excellent job.

Thanks for supplying these kinds of very helpful information. Congrats in becoming an exceptional blogger.

Hay otras soluciones para evitar hacer soldaduras, y es el uso de un sistema de unión con sistema de bloqueo BLS. Se utiliza incluso para presiones de hasta 100 bar con garantía antidesconexión. No requiere de especialista para la instalación.

Visitar videos en www.construtec.es

El material es similar al acero, en hierro dúctil.

El blog es muy interesante, y debería ser más participativo.

Saludos desde España.

Very very interesting post..I like this one. gotta bookmark this one.Your work is fantastic looking, the site is a snap to navigate... Consider me a fan!

PoIuYt

Post a Comment